All Issues

Spring

2024

Spring

2024

Where Passion Meets Purpose

2024-2025 Initiators Fellows are leveraging lived experiences to drive meaningful social change.

Read Issue Fall

2023

Fall

2023

Building Back Better

One year in: Special grants help nonprofits transform post-pandemic services.

Read Issue Spring

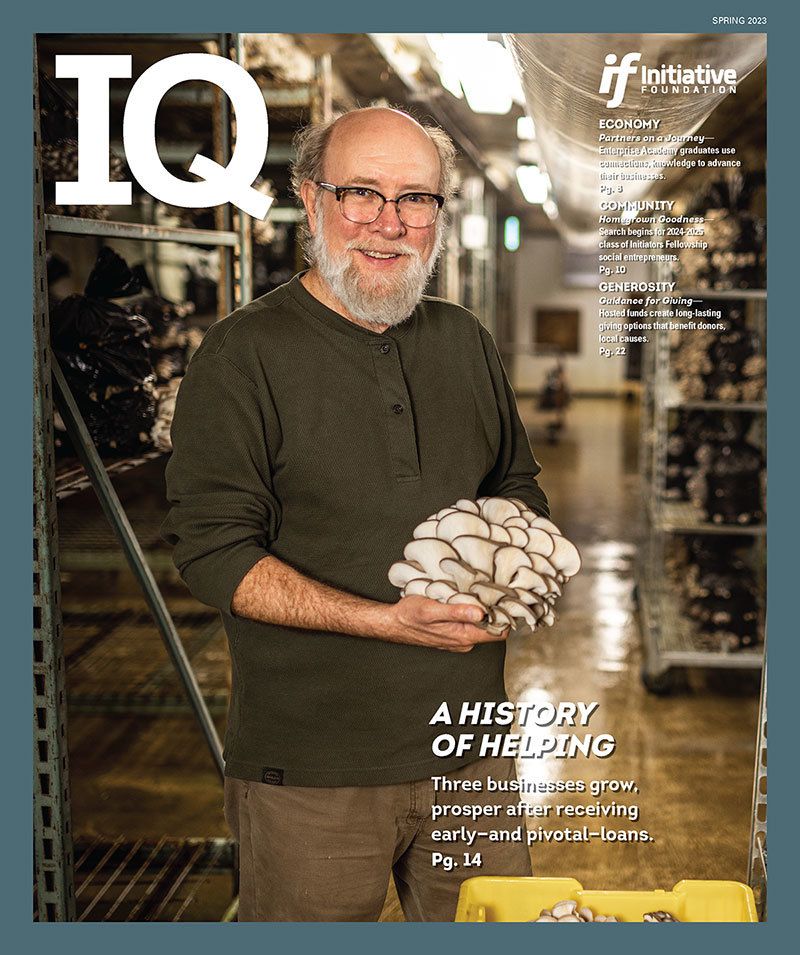

2023

Spring

2023

A History of Helping

Lending initiatives help entrepreneurs launch, expand, provide stability in communities they help anchor

Read Issue Fall

2022

Fall

2022

Granting With Gratitude

Nearly $26 million helps small businesses, nonprofits survive two-plus years of uncertainty.

Read Issue Spring

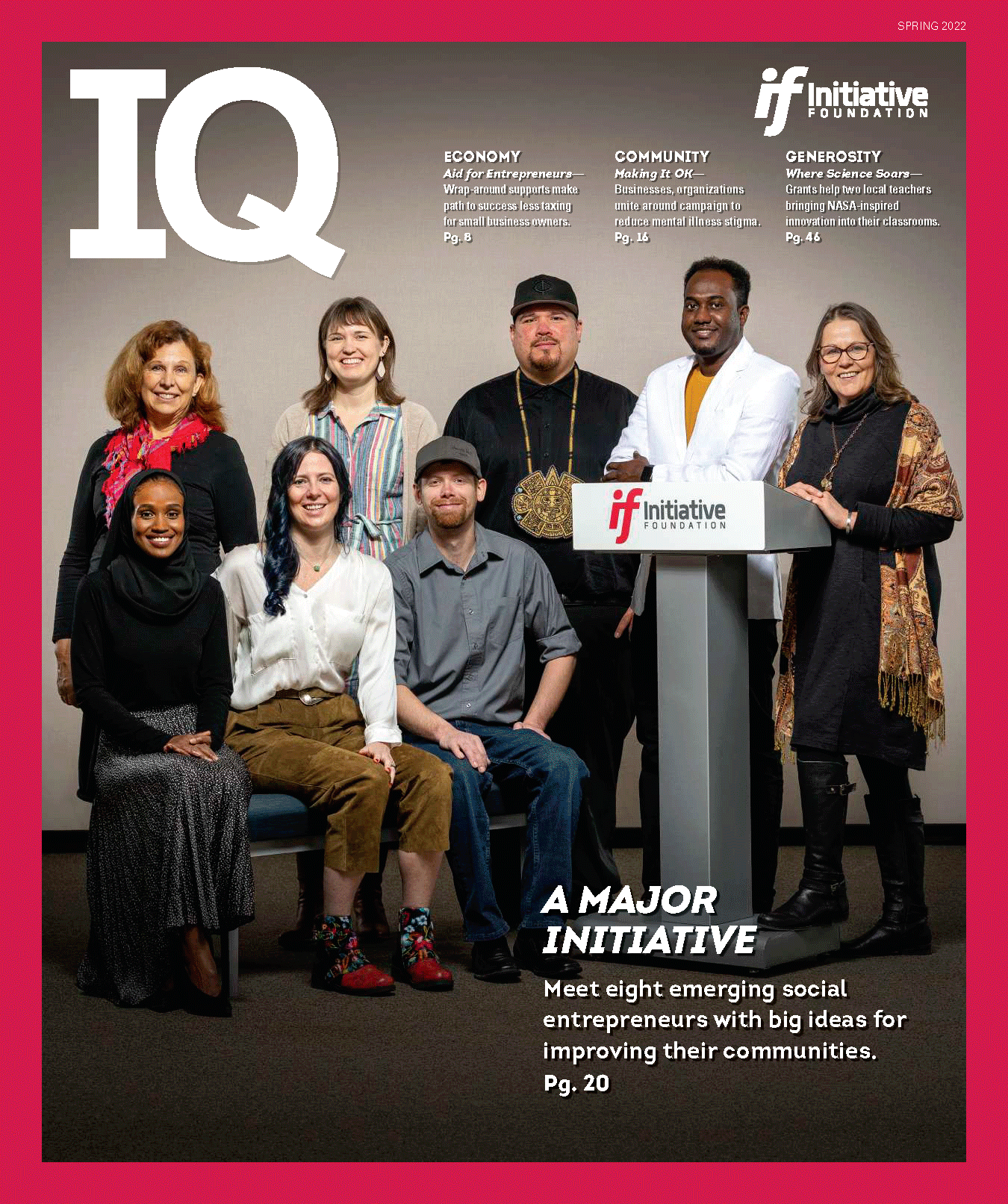

2022

Spring

2022

A Major Initiative

Meet emerging social entrepreneurs poised to improve their communities.

Read Issue Fall

2021

Fall

2021

Entrepreneurial Spirit

Lending program helps growing companies expand, exceed goals and create jobs.

Read Issue- 1

- 2